Innovative Trunnion Mounted Ball Control Valve Redefines Industry Standards

In a significant development for the fluid control industry, a groundbreaking Trunnion mounted ball control valve has been introduced, promising enhanced efficiency and durability in industrial applications. Engineered to excel in high-pressure environments and adverse conditions, this valve represents a leap forward in valve technology.

The Trunnion mounted ball control valve is meticulously crafted to ensure optimal performance in long-distance pipelines and various industrial settings. Its robust construction and resilient design make it a standout choice for critical operations where reliability is paramount.

With features such as enhanced polytetrafluoroethylene (PTFE) sealing and self-tightening characteristics, this valve guarantees consistent and reliable sealing even under extreme conditions. Its bidirectional capability and flexible installation options further enhance its versatility, making it suitable for a wide range of applications.

Notably, the valve's innovative design minimizes torque and seat deformation, resulting in stable sealing performance and an extended service life. This makes it an ideal choice for industries requiring high-pressure and large-diameter solutions.

Furthermore, the valve's fire-resistant design and automatic pressure relief mechanism ensure enhanced safety and peace of mind for operators. Its efficient drainage system enables easy maintenance and minimizes medium contamination, contributing to overall operational efficiency.

Advantages in Performance:

1. Seamless Operation: The upper and lower bearings provide crucial support to the ball, effectively reducing friction and torque stemming from sealing loads.

2. Reliable Sealing: Enhanced by a PTFE single-material sealing ring nestled within a stainless steel seat, and fortified with a rear spring for consistent pre-tightening force, the valve ensures enduring sealing performance, resilient even to surface wear.

3. Fire-Resistant Design: Engineered with a fire-resistant sealing ring positioned between the ball and valve seat, the valve guarantees a metal-to-metal seal, preventing significant leakage in the event of PTFE ring burning.

4. Automatic Pressure Relief: Should pressure within the valve chamber exceed the spring's pre-set force, the valve seat automatically retracts from the ball, facilitating instant pressure relief before returning to its original position.

5. Efficient Drainage: Equipped with upper and lower drainage apertures, the valve streamlines leak detection, simplifies packing replacement, and enables the discharge of retained substances during full open or closed states, thereby mitigating medium contamination.

In summary, the introduction of the Trunnion mounted ball control valve marks a significant milestone in valve technology, offering unparalleled performance, durability, and safety features. As industries continue to demand reliable solutions for fluid control, this innovative valve sets a new standard for excellence.

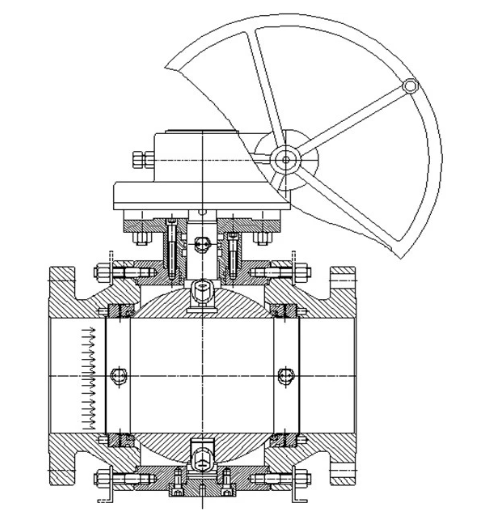

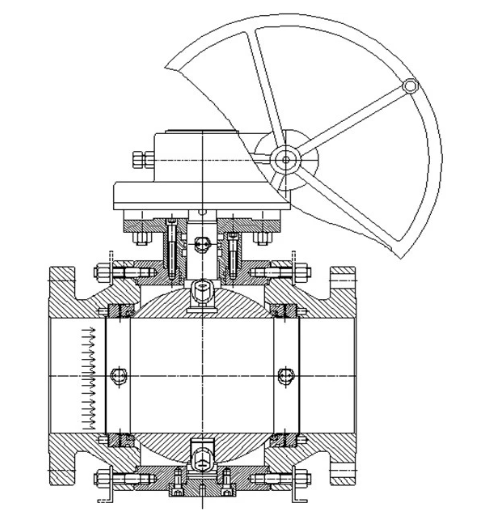

Drawing of Trunnion Mounted Ball Control Valve

The Trunnion mounted ball control valve is meticulously crafted to ensure optimal performance in long-distance pipelines and various industrial settings. Its robust construction and resilient design make it a standout choice for critical operations where reliability is paramount.

With features such as enhanced polytetrafluoroethylene (PTFE) sealing and self-tightening characteristics, this valve guarantees consistent and reliable sealing even under extreme conditions. Its bidirectional capability and flexible installation options further enhance its versatility, making it suitable for a wide range of applications.

Notably, the valve's innovative design minimizes torque and seat deformation, resulting in stable sealing performance and an extended service life. This makes it an ideal choice for industries requiring high-pressure and large-diameter solutions.

Furthermore, the valve's fire-resistant design and automatic pressure relief mechanism ensure enhanced safety and peace of mind for operators. Its efficient drainage system enables easy maintenance and minimizes medium contamination, contributing to overall operational efficiency.

Advantages in Performance:

1. Seamless Operation: The upper and lower bearings provide crucial support to the ball, effectively reducing friction and torque stemming from sealing loads.

2. Reliable Sealing: Enhanced by a PTFE single-material sealing ring nestled within a stainless steel seat, and fortified with a rear spring for consistent pre-tightening force, the valve ensures enduring sealing performance, resilient even to surface wear.

3. Fire-Resistant Design: Engineered with a fire-resistant sealing ring positioned between the ball and valve seat, the valve guarantees a metal-to-metal seal, preventing significant leakage in the event of PTFE ring burning.

4. Automatic Pressure Relief: Should pressure within the valve chamber exceed the spring's pre-set force, the valve seat automatically retracts from the ball, facilitating instant pressure relief before returning to its original position.

5. Efficient Drainage: Equipped with upper and lower drainage apertures, the valve streamlines leak detection, simplifies packing replacement, and enables the discharge of retained substances during full open or closed states, thereby mitigating medium contamination.

In summary, the introduction of the Trunnion mounted ball control valve marks a significant milestone in valve technology, offering unparalleled performance, durability, and safety features. As industries continue to demand reliable solutions for fluid control, this innovative valve sets a new standard for excellence.