Understanding Pneumatic Single-Seat Globe Control Valves

On this page

Pneumatic Single-Seat Globe Control Valves are engineered to handle high differential pressure applications and heavy-duty service environments. These valves excel in conditions where fluid differential pressures exceed 2940 kPa (30 kgf/cm²) or where issues like flashing and cavitation may arise. With a robust design and advanced features, these control valves ensure optimal performance, durability, and reliability under demanding conditions.

FC (Fail Close): Air-to-open mechanism paired with a reverse-action actuator. Equal percentage: Suitable for applications requiring smooth and predictable flow changes.

Linear: Ideal for operations demanding a consistent rate of flow change.

Metal Seat: Complies with ANSI B16.104 Class II standards, ensuring leakage is less than 0.5% of the maximum valve capacity.

Soft Seat: Complies with ANSI B16.104 Class VI standards, achieving ultra-tight sealing with leakage less than 0.00001% of the maximum valve capacity. These valves are designed for a wide range of industries and applications, including:

FC (Fail Close): Air-to-open mechanism paired with a reverse-action actuator. Equal percentage: Suitable for applications requiring smooth and predictable flow changes.

Linear: Ideal for operations demanding a consistent rate of flow change.

Soft Seat: Complies with ANSI B16.104 Class VI standards, achieving ultra-tight sealing with leakage less than 0.00001% of the maximum valve capacity. These valves are designed for a wide range of industries and applications, including:

Handling high-pressure fluids in refining, processing, and transportation systems.

Managing aggressive chemicals and high-pressure reactions with precision.

Regulating steam, water, and other fluids in boilers and turbines.

Controlling flow in high-pressure filtration and desalination systems.

Their robust construction and advanced features make them ideal for environments where reliability and precision are paramount.

Their robust construction and advanced features make them ideal for environments where reliability and precision are paramount.

The sturdy guides in the valve ensure smooth and accurate movement of the valve plug, enhancing control precision. Additionally, the cage design offers dual benefits:

It protects the valve body from the effects of cavitation and flashing, which can cause material degradation over time.

It provides mechanical support to withstand the impact of high differential pressures, ensuring long-term operational stability.

It protects the valve body from the effects of cavitation and flashing, which can cause material degradation over time.

It provides mechanical support to withstand the impact of high differential pressures, ensuring long-term operational stability.

The valves utilize compact diaphragm actuators that are loaded with multiple springs. This design enhances responsiveness and provides reliable control under various operating conditions. The actuator's compact size also contributes to space efficiency in installations with limited room.

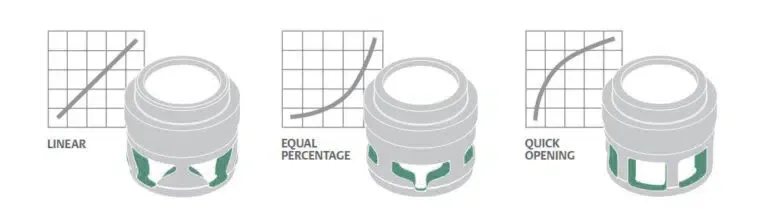

The availability of both equal percentage and linear flow characteristics allows these valves to accommodate a wide array of system requirements:

This characteristic is ideal for processes where small changes in valve position result in increasingly larger changes in flow rate, ensuring stability in applications with varying pressure drops.

Provides a consistent relationship between valve position and flow rate, making it suitable for processes requiring steady and predictable control.

Leakage control is a critical aspect of valve performance, and these valves meet stringent standards to minimize leakage:

Metal Seats: Designed for applications where minor leakage is acceptable, providing reliability for general-purpose use.

Soft Seats: Achieve near-zero leakage, making them suitable for applications requiring tight shutoff, such as handling expensive or hazardous fluids.

Metal Seats: Designed for applications where minor leakage is acceptable, providing reliability for general-purpose use.

Soft Seats: Achieve near-zero leakage, making them suitable for applications requiring tight shutoff, such as handling expensive or hazardous fluids.

Choosing the right control valve is crucial for system efficiency and reliability. Pneumatic Single-Seat Globe Control Valves stand out due to their:

Built to handle challenging environments and high-pressure conditions.

Offers customizable flow characteristics and tight shutoff capabilities.

Suitable for a wide range of industrial applications, ensuring consistent performance.

Compact design simplifies maintenance procedures, reducing downtime.

Pneumatic Single-Seat Globe Control Valves are the go-to solution for high differential pressure and heavy-duty service applications. Their robust construction, advanced design features, and superior performance capabilities make them indispensable for industries that demand reliability and precision.

Whether managing complex fluid systems in the oil and gas sector or ensuring precise flow control in chemical processing, these valves provide a dependable and efficient solution for modern industrial needs. By incorporating these valves into your system, you can enhance operational efficiency, reduce maintenance costs, and ensure long-term performance in the most demanding environments.

Whether managing complex fluid systems in the oil and gas sector or ensuring precise flow control in chemical processing, these valves provide a dependable and efficient solution for modern industrial needs. By incorporating these valves into your system, you can enhance operational efficiency, reduce maintenance costs, and ensure long-term performance in the most demanding environments.