In the world of heating, ventilation, and air conditioning (HVAC) systems, maintaining optimal pressure and flow rates is crucial for efficient and safe operation. Differential Pressure Control Valves (DPCVs) play a vital role in achieving this balance. These specialized valves are designed to regulate and maintain pressure within specific sub-circuits of heating or cooling systems, ensuring that equipment operates within its designed parameters. By preventing excessive pressure differentials, DPCVs protect system components, enhance energy efficiency, and contribute to the overall reliability of HVAC systems. This article delves into the functionality, applications, installation, and benefits of differential pressure control valves, providing a comprehensive understanding of their importance in modern HVAC systems.

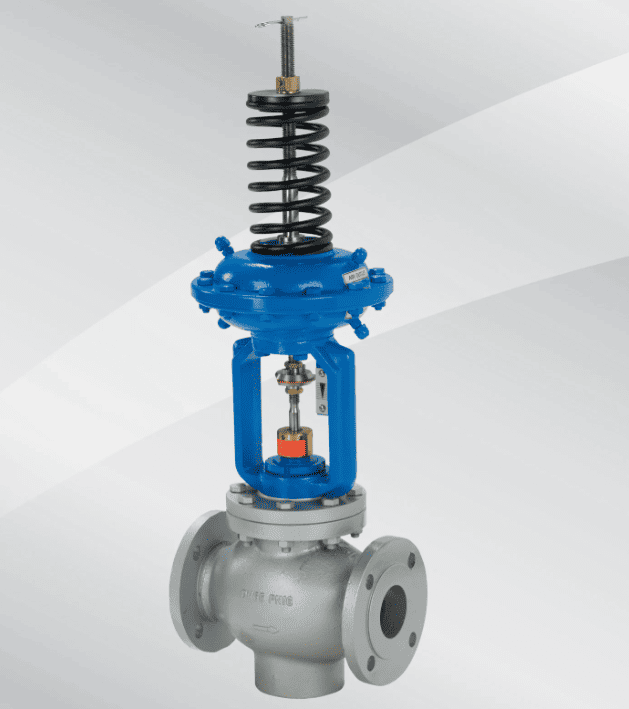

Differential Pressure Control Valves, often abbreviated as DPCVs, are mechanical devices installed in heating or cooling systems to regulate and control the pressure within sub-circuits. Their primary function is to maintain a set or maximum pressure differential (ΔP) across a specific section of the system, thereby limiting the flow rate at full load conditions. By doing so, DPCVs ensure that the system operates within safe and efficient parameters, preventing damage to equipment and optimizing performance.

DPCVs are commonly used in hydronic heating systems, chilled water loops, and other HVAC applications where pressure regulation is critical. These valves are particularly useful in systems with variable flow rates, such as those equipped with pumps or fans that adjust their output based on demand. By stabilizing pressure differentials, DPCVs help maintain consistent system performance, even under fluctuating load conditions.

In hydronic heating systems, DPCVs are used to control the pressure in sub-circuits, such as radiators or underfloor heating loops. By maintaining a consistent pressure differential, these valves ensure even heat distribution and prevent over-pressurization, which can lead to equipment failure or leaks.

DPCVs are essential in chilled water loops, where they help maintain a constant pressure differential across the chiller. This ensures that the chiller operates within its designed pressure range, preventing damage and optimizing cooling efficiency.

In systems with variable flow rates, such as those using variable speed pumps, DPCVs play a critical role in stabilizing pressure differentials. This is particularly important in large or complex systems where pressure fluctuations can lead to inefficiencies or equipment malfunctions.

By preventing excessive pressure differentials, DPCVs contribute to energy efficiency. They reduce the workload on pumps and other equipment, leading to lower energy consumption and operational costs.

The proper installation of a differential pressure control valve is crucial for its effective operation. Below, we explore the key considerations for installing DPCVs in different types of systems.

In chilled water systems, the differential pressure control valve is typically installed on the bypass line between the supply and return piping of the chiller. This valve, often referred to as a differential pressure bypass valve or pressure relief valve, is designed to maintain a constant pressure differential (ΔP) across the chiller.

When the pressure drop across the chiller exceeds a predetermined set point, the valve opens, allowing water to flow through the bypass line instead of the chiller. This ensures that the chiller operates within its designed pressure range, protecting it from damage and maintaining system efficiency.

Key Installation Tips for Chilled Water Loops:

Ensure the valve is properly sized for the flow rate and pressure drop across the chiller.

Install the valve in an accessible location for easy maintenance and adjustment.

Consult the chiller manufacturer's installation manual and system design documents to ensure compliance with specifications.

In heating systems, DPCVs are typically installed in sub-circuits, such as radiator loops or underfloor heating systems. The valve should be positioned to control the pressure differential across the specific sub-circuit, ensuring even heat distribution and preventing over-pressurization.

Key Installation Tips for Heating Systems:

Position the valve close to the sub-circuit it is intended to regulate.

Ensure the valve is compatible with the system's operating temperature and pressure.

Regularly inspect and maintain the valve to ensure optimal performance.

By maintaining consistent pressure differentials, DPCVs protect sensitive equipment, such as chillers, pumps, and heat exchangers, from damage caused by over-pressurization or pressure fluctuations.

DPCVs reduce the workload on pumps and other equipment by stabilizing pressure differentials, leading to lower energy consumption and operational costs.

By preventing pressure-related issues, DPCVs enhance the reliability and longevity of HVAC systems, reducing the risk of downtime and costly repairs.

In heating and cooling systems, DPCVs ensure even distribution of heat or cooling, enhancing occupant comfort and satisfaction.

DPCVs help HVAC systems comply with industry standards and regulations, ensuring safe and efficient operation.

Differential Pressure Control Valves are indispensable components in modern HVAC systems, providing critical pressure regulation and ensuring efficient, reliable operation. Whether installed in chilled water loops, hydronic heating systems, or variable flow applications, DPCVs play a vital role in protecting equipment, enhancing energy efficiency, and maintaining system performance. By understanding the functionality, applications, and installation requirements of these valves, HVAC professionals can optimize system design and operation, delivering superior comfort and performance while minimizing operational costs. As the demand for energy-efficient and sustainable HVAC solutions continues to grow, the importance of differential pressure control valves will only increase, solidifying their place as a cornerstone of modern building systems.