What is Double Eccentric Butterfly Control Valve?

On this page

The double eccentric butterfly control valve is a critical component in modern fluid control systems, offering superior performance and reliability in various industrial applications. This article provides an in-depth look at the different types, applications, working principles, advantages, and features of double eccentric butterfly control valves, emphasizing their importance in contemporary engineering and industrial processes.

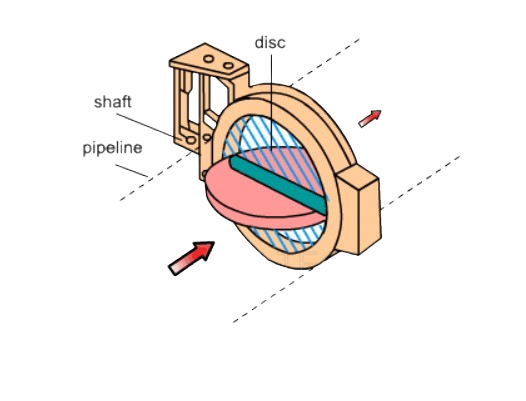

Double eccentric butterfly control valves, also known as double offset butterfly valves, are designed to improve sealing capabilities and extend the valve's lifespan. These valves differ from traditional butterfly valves by incorporating two distinct offsets: one in the valve's shaft and another in the seat. This double offset design ensures that the valve disc moves away from the seat rapidly during operation, reducing wear and tear and enhancing the valve's sealing efficiency. The result is a valve that provides a tighter seal with minimal leakage, even in challenging environments where standard butterfly valves may fail.

Understanding the different types of double eccentric butterfly control valves is essential for selecting the right valve for specific applications. The main types include: The double offset butterfly valve features two offsets: one at the centerline of the shaft and another at the centerline of the seat. This design reduces the contact between the disc and seat during operation, minimizing friction and wear. The double offset design is particularly effective in applications where a tight seal and long service life are crucial. The triple offset butterfly valve adds a third offset to the design, creating a cone-shaped sealing surface that minimizes friction even further. This advanced sealing mechanism makes the triple offset valve ideal for high-pressure and high-temperature environments, offering exceptional performance and reliability.

The mechanism used to operate the valve, which can be manual (using a handle or lever) or automated (using an electric, pneumatic, or hydraulic actuator).

The mechanism used to operate the valve, which can be manual (using a handle or lever) or automated (using an electric, pneumatic, or hydraulic actuator).

When the valve is closed, the disc seals tightly against the seat, preventing fluid from passing through. As the actuator rotates the disc, it moves away from the seat, allowing fluid to flow through the valve. This simple yet effective mechanism provides precise control over flow rates, making the valve suitable for both throttling (regulating flow) and on/off (completely open or closed) applications.

Double eccentric butterfly valves offer several advantages over traditional valve designs, making them a preferred choice in many industries: The double offset design improves sealing capabilities by minimizing the contact between the disc and seat during operation. This reduces wear and tear, ensuring a tight seal and minimizing leakage even in high-pressure and high-temperature applications. By reducing friction and wear on the sealing surfaces, double eccentric butterfly valves offer extended service life. This durability translates to lower maintenance costs and reduced downtime for repairs or replacements. These valves can handle a wide range of fluids, including liquids, gases, and slurries, as well as varying temperatures and pressures. This versatility makes them suitable for diverse applications across multiple industries. Double eccentric butterfly valves have a compact and lightweight design compared to other valve types, such as gate valves and ball valves. This compactness simplifies installation and maintenance, reducing space requirements and associated costs. Despite their advanced design and performance capabilities, double eccentric butterfly valves are often more cost-effective than other high-performance valve types. Their relatively low manufacturing and maintenance costs make them an attractive option for many applications. Whether used in low-pressure systems or high-pressure environments, these valves deliver consistent and reliable performance. Their robust construction and efficient sealing mechanisms ensure dependable operation in even the most demanding conditions. Maintaining your double offset butterfly valve is crucial for ensuring optimal performance. Regularly inspect the valve for signs of wear or damage, paying close attention to connections, seals, and components prone to failure. Grease the threads and seal faces each time you operate the valve to maintain a secure fit. Preferably use a hand wheel over an actuator to reduce stress on the valve and simplify maintenance. Consider installing the valve with corrosion-resistant materials to enhance longevity and efficiency. The double eccentric butterfly control valve stands out as a versatile and efficient solution for fluid control in a variety of industries. Its innovative double offset design, combined with its robust performance and durability, makes it a preferred choice for engineers and operators seeking optimal performance and reliability in fluid handling applications. From oil and gas to chemical processing, water treatment, HVAC systems, and power generation, the double eccentric butterfly valve continues to play a vital role in modern industrial processes, ensuring precise control, enhanced sealing, and long-term operational success.

Understanding the different types of double eccentric butterfly control valves is essential for selecting the right valve for specific applications. The main types include: The double offset butterfly valve features two offsets: one at the centerline of the shaft and another at the centerline of the seat. This design reduces the contact between the disc and seat during operation, minimizing friction and wear. The double offset design is particularly effective in applications where a tight seal and long service life are crucial. The triple offset butterfly valve adds a third offset to the design, creating a cone-shaped sealing surface that minimizes friction even further. This advanced sealing mechanism makes the triple offset valve ideal for high-pressure and high-temperature environments, offering exceptional performance and reliability.

Triple Offset Butterfly Control Valve

In a concentric butterfly valve, the disc and shaft are aligned along the same centerline, providing a simpler and more cost-effective solution. While concentric valves may not offer the same level of sealing performance as double or triple offset valves, they are suitable for applications where moderate sealing capabilities are sufficient.

PTFE (Polytetrafluoroethylene) lined butterfly valves are designed to handle corrosive fluids, thanks to their excellent chemical resistance. The PTFE lining protects the valve's internal components from corrosive substances, making these valves ideal for use in chemical processing, pharmaceuticals, and other industries dealing with aggressive fluids.

Double eccentric butterfly control valves are utilized across a wide range of industries due to their versatility and reliability. Some common applications include:

In the oil and gas industry, these valves are used for controlling the flow of crude oil, natural gas, and other hydrocarbons. Their ability to withstand high pressures and harsh conditions makes them indispensable in upstream, midstream, and downstream operations.

Chemical plants require precise control over fluid flow to ensure safety and efficiency. Double eccentric butterfly valves provide the necessary sealing performance and chemical resistance to handle a variety of aggressive chemicals

In water treatment facilities, these valves are used for regulating the flow of water and wastewater. Their durability and reliability make them ideal for handling the continuous operation and varying pressures found in these systems.

Heating, ventilation, and air conditioning (HVAC) systems rely on efficient fluid control to maintain optimal performance. Double eccentric butterfly valves are used to regulate the flow of heating and cooling fluids, ensuring consistent temperatures and energy efficiency.

Power plants use these valves to control the flow of steam, water, and other fluids in their processes. The robust design and high-performance capabilities of double eccentric butterfly valves make them suitable for the demanding conditions found in power generation facilities.

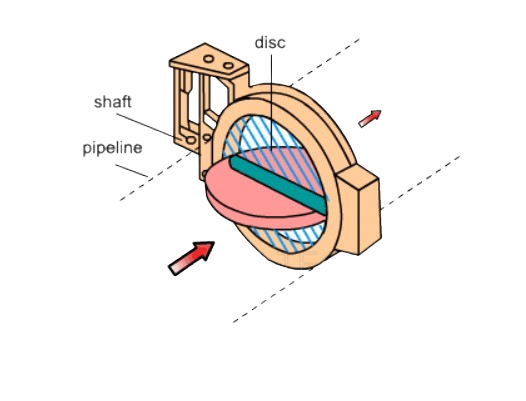

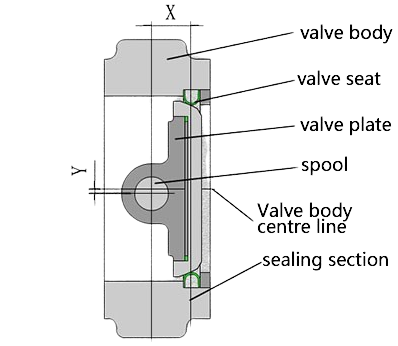

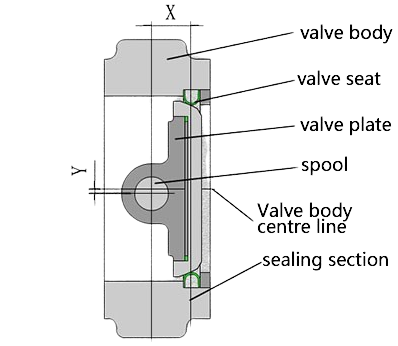

The operation of a double eccentric butterfly control valve is based on the rotation of a disc (or butterfly) within the valve body to regulate fluid flow. The key components and their functions include:

The outer casing that houses the internal components and provides a connection to the pipeline.

The rotating element that controls the flow of fluid through the valve. When the disc is aligned with the flow path, fluid can pass through; when it is perpendicular, the flow is blocked.

The sealing surface against which the disc closes to prevent fluid passage. The double offset design ensures that the disc moves away from the seat quickly during operation, reducing wear and improving sealing performance.

The component that connects the disc to the actuator or handle, allowing for the rotation of the disc. The mechanism used to operate the valve, which can be manual (using a handle or lever) or automated (using an electric, pneumatic, or hydraulic actuator).

The mechanism used to operate the valve, which can be manual (using a handle or lever) or automated (using an electric, pneumatic, or hydraulic actuator).When the valve is closed, the disc seals tightly against the seat, preventing fluid from passing through. As the actuator rotates the disc, it moves away from the seat, allowing fluid to flow through the valve. This simple yet effective mechanism provides precise control over flow rates, making the valve suitable for both throttling (regulating flow) and on/off (completely open or closed) applications.

Double eccentric butterfly valves offer several advantages over traditional valve designs, making them a preferred choice in many industries: The double offset design improves sealing capabilities by minimizing the contact between the disc and seat during operation. This reduces wear and tear, ensuring a tight seal and minimizing leakage even in high-pressure and high-temperature applications. By reducing friction and wear on the sealing surfaces, double eccentric butterfly valves offer extended service life. This durability translates to lower maintenance costs and reduced downtime for repairs or replacements. These valves can handle a wide range of fluids, including liquids, gases, and slurries, as well as varying temperatures and pressures. This versatility makes them suitable for diverse applications across multiple industries. Double eccentric butterfly valves have a compact and lightweight design compared to other valve types, such as gate valves and ball valves. This compactness simplifies installation and maintenance, reducing space requirements and associated costs. Despite their advanced design and performance capabilities, double eccentric butterfly valves are often more cost-effective than other high-performance valve types. Their relatively low manufacturing and maintenance costs make them an attractive option for many applications. Whether used in low-pressure systems or high-pressure environments, these valves deliver consistent and reliable performance. Their robust construction and efficient sealing mechanisms ensure dependable operation in even the most demanding conditions. Maintaining your double offset butterfly valve is crucial for ensuring optimal performance. Regularly inspect the valve for signs of wear or damage, paying close attention to connections, seals, and components prone to failure. Grease the threads and seal faces each time you operate the valve to maintain a secure fit. Preferably use a hand wheel over an actuator to reduce stress on the valve and simplify maintenance. Consider installing the valve with corrosion-resistant materials to enhance longevity and efficiency. The double eccentric butterfly control valve stands out as a versatile and efficient solution for fluid control in a variety of industries. Its innovative double offset design, combined with its robust performance and durability, makes it a preferred choice for engineers and operators seeking optimal performance and reliability in fluid handling applications. From oil and gas to chemical processing, water treatment, HVAC systems, and power generation, the double eccentric butterfly valve continues to play a vital role in modern industrial processes, ensuring precise control, enhanced sealing, and long-term operational success.