What is a Multi-Port Ball Control Valve?

On this page

Multi-port ball control valves are essential components in sophisticated industrial systems, offering advanced control over fluid flow through multiple channels. Unlike traditional single-port valves, multi-port ball control valves are designed to handle several flow paths simultaneously, making them indispensable in applications requiring complex flow management and precise control. These valves are engineered to manage the flow of liquids or gases through various ports, providing flexibility and efficiency in a wide range of processes.

4-Way Ball Control Valves Operations

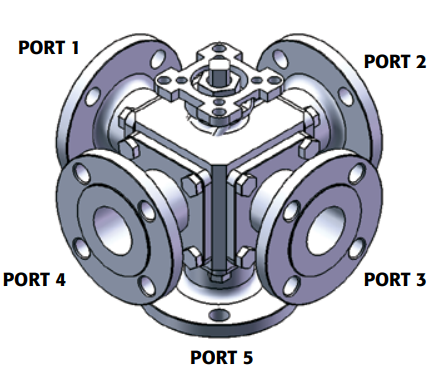

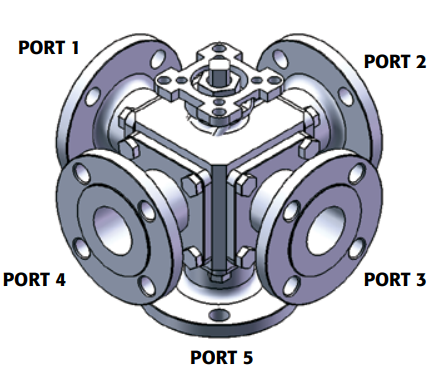

5-way ball control valves are less common but offer additional control options with five ports. These valves are employed in more complex systems where multiple flow paths need to be managed simultaneously. The 5-way design allows for intricate flow routing and management, making it suitable for advanced applications where several processes or components require simultaneous control. Examples of such applications include specialized industrial processes or multi-functional systems that require precise and coordinated fluid distribution.

The choice of materials for multi-port ball control valves is critical to their performance, longevity, and suitability for various applications. Common materials include: Stainless steel, such as grades ASTM A316 or ASTM A182 F316, is renowned for its excellent resistance to corrosion and high strength. It is commonly used in applications involving harsh environments, corrosive fluids, or high temperatures. Stainless steel valves ensure long-term reliability and durability, making them ideal for critical applications in industries such as chemical processing and pharmaceuticals. Brass is a popular material choice for its machinability, corrosion resistance, and cost-effectiveness. It is suitable for a range of industrial applications where environmental conditions are less severe. Brass valves are often used in water treatment facilities and general industrial processes where moderate corrosion resistance is adequate. Carbon steel is selected for its strength and durability. It is used in applications where high pressure and temperature conditions are present, but where the environment is not highly corrosive. Carbon steel valves are commonly found in oil and gas industries and other heavy-duty applications. Plastic and composite materials, such as PVC, CPVC, or fluoropolymers, offer excellent resistance to chemical attack and are lightweight. These materials are used in applications where chemical resistance is critical, and where operating pressures are lower. Plastic valves are commonly used in the pharmaceutical industry, food processing, and other applications involving aggressive chemicals. Multi-port ball control valves operate using a spherical ball with multiple ports that rotates within a chamber. The ball's ports align with the valve’s external ports to control the direction and flow of fluids. Here's an overview of their operation: The valve's ball contains multiple ports, each connected to different flow paths. The arrangement of these ports determines how the valve directs the flow.

Application Requirements: Identify the specific needs of your application, including the number of flow paths and the type of fluid being controlled. Select a valve type (3-way, 4-way, or 5-way) that aligns with your process requirements. Ensure that the valve materials are compatible with the fluids handled. Consider factors such as temperature, pressure, and corrosiveness to select the right material. Verify that the valve can handle the pressure and temperature conditions of your application. Opt for a valve with appropriate ratings to ensure reliable and safe operation. Match the valve size and connection type with your system's specifications. Proper sizing and connection ensure efficient performance and seamless integration with existing infrastructure. Evaluate the ease of maintenance and the valve’s expected lifespan. Choose a valve with durable materials and design features that minimize maintenance needs and ensure long-term reliability. Multi-port ball control valves offer significant advantages for managing complex fluid systems. By understanding the various types, materials, and operational principles, you can select the right valve to enhance efficiency and performance in your specific applications.

3-Way, 4-Way, 5-Way Ball Control Valves

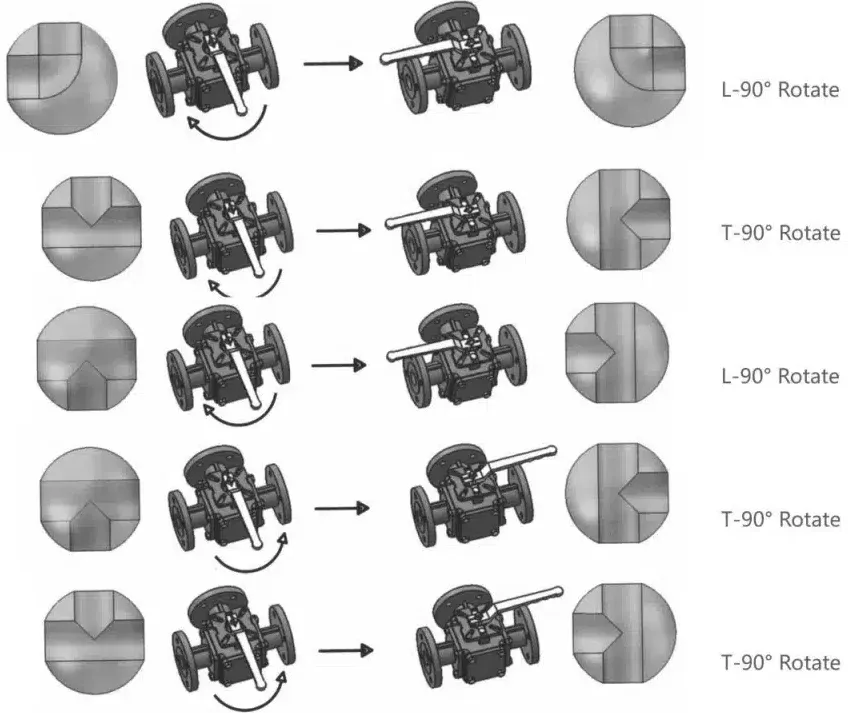

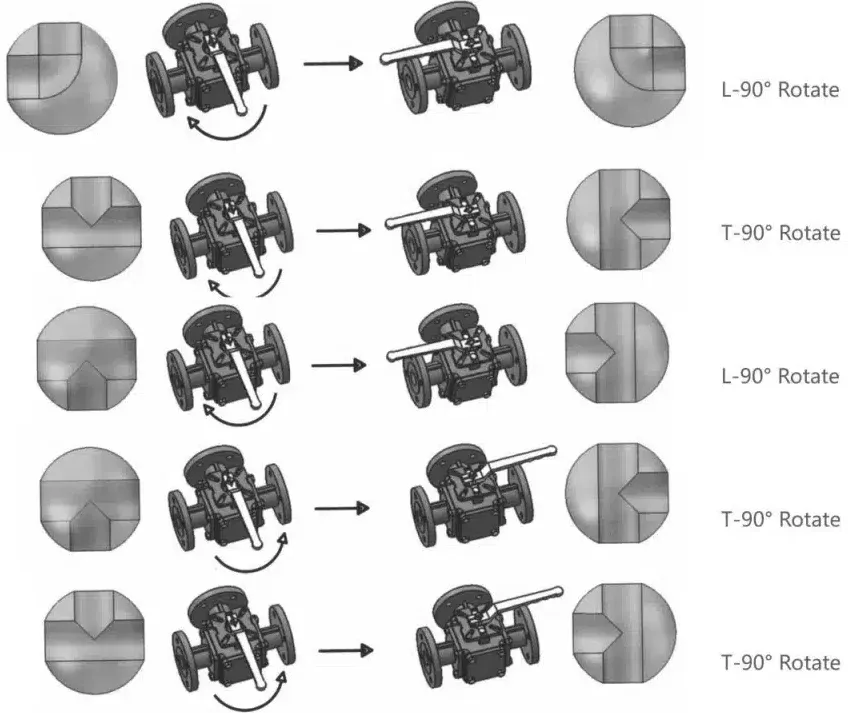

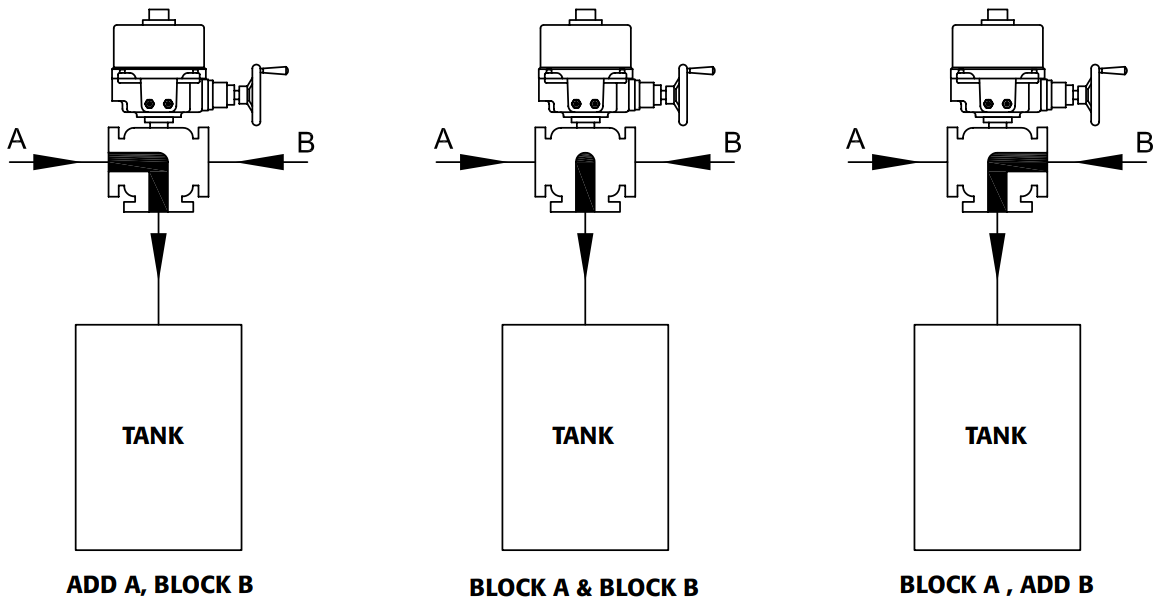

3-way ball control valves are among the most prevalent types of multi-port valves. They are characterized by their three ports, typically arranged in an "L" or "T" configuration. These valves are engineered to either mix flows from two different sources or divert flow from a single inlet to two different outlets. The internal ball has three ports, allowing for versatile flow routing. This design is especially valuable in applications where precise flow diversion or blending of two fluids is required. For example, in HVAC systems, 3-way valves can be used to blend hot and cold water to achieve a desired temperature.

3-Way Ball Control Valves Operation

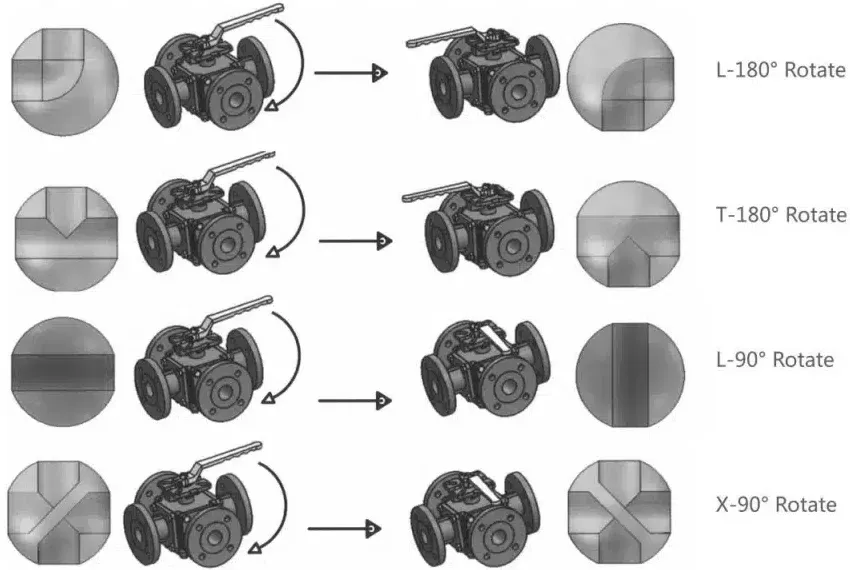

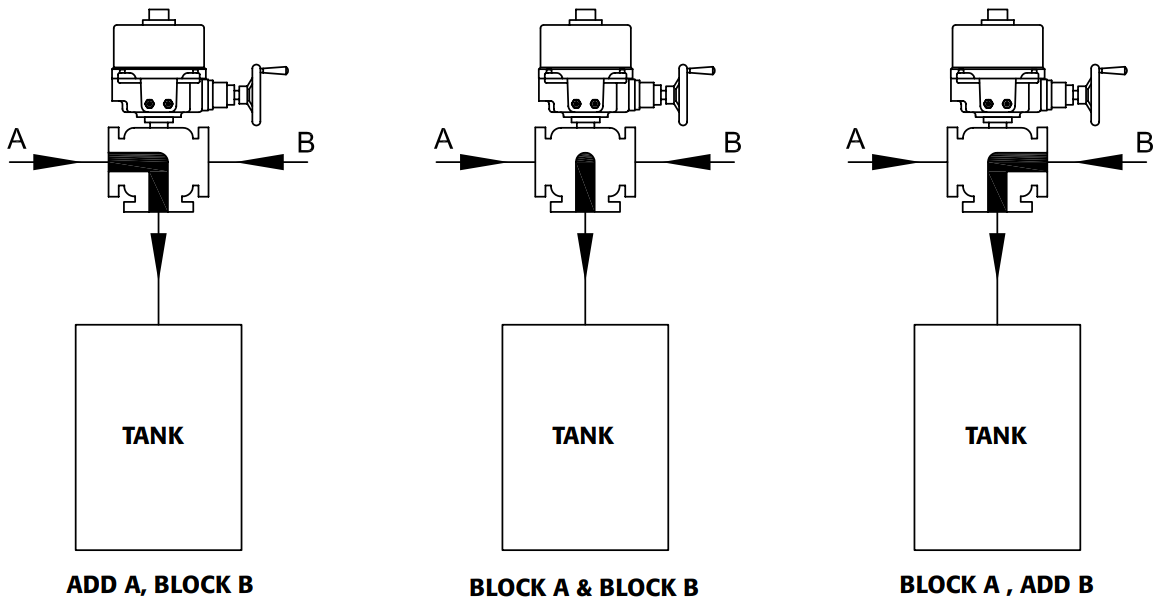

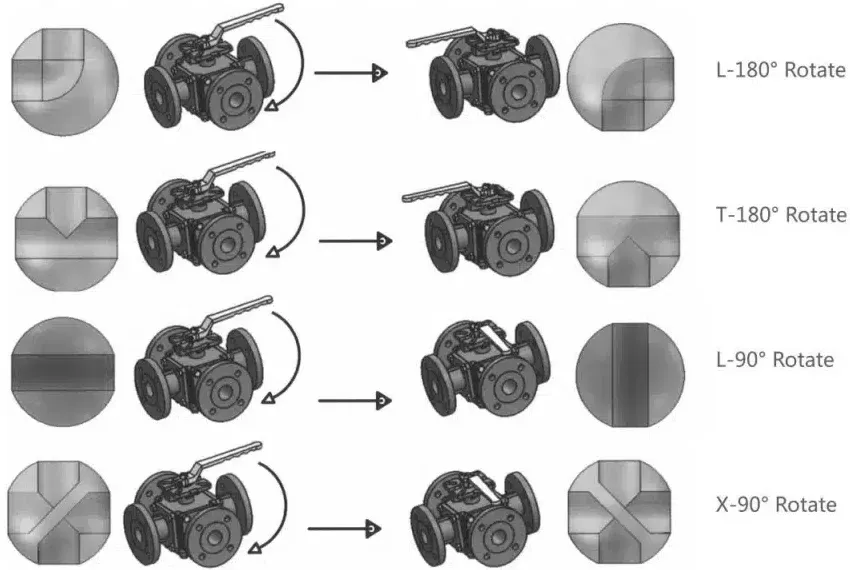

4-way ball control valves provide enhanced flexibility with their four-port design. They are particularly useful in systems where the flow needs to be distributed to multiple destinations or where complex flow patterns are necessary. These valves are commonly used in hydraulic systems to control the direction of fluid flow to multiple actuators or components from a single valve unit. The 4-way configuration enables the control of flow in various directions, making it ideal for applications requiring precise management of fluid distribution, such as in manufacturing processes or automation systems.

4-Way Ball Control Valves Operations

The choice of materials for multi-port ball control valves is critical to their performance, longevity, and suitability for various applications. Common materials include: Stainless steel, such as grades ASTM A316 or ASTM A182 F316, is renowned for its excellent resistance to corrosion and high strength. It is commonly used in applications involving harsh environments, corrosive fluids, or high temperatures. Stainless steel valves ensure long-term reliability and durability, making them ideal for critical applications in industries such as chemical processing and pharmaceuticals. Brass is a popular material choice for its machinability, corrosion resistance, and cost-effectiveness. It is suitable for a range of industrial applications where environmental conditions are less severe. Brass valves are often used in water treatment facilities and general industrial processes where moderate corrosion resistance is adequate. Carbon steel is selected for its strength and durability. It is used in applications where high pressure and temperature conditions are present, but where the environment is not highly corrosive. Carbon steel valves are commonly found in oil and gas industries and other heavy-duty applications. Plastic and composite materials, such as PVC, CPVC, or fluoropolymers, offer excellent resistance to chemical attack and are lightweight. These materials are used in applications where chemical resistance is critical, and where operating pressures are lower. Plastic valves are commonly used in the pharmaceutical industry, food processing, and other applications involving aggressive chemicals. Multi-port ball control valves operate using a spherical ball with multiple ports that rotates within a chamber. The ball's ports align with the valve’s external ports to control the direction and flow of fluids. Here's an overview of their operation: The valve's ball contains multiple ports, each connected to different flow paths. The arrangement of these ports determines how the valve directs the flow.

3-WAY BALL VALVE WITH VERTICAL L-PORT

The internal ball rotates to align its ports with the valve’s external ports. This rotation controls the flow direction and distribution. For instance, a 3-way valve can direct flow to one of two outlets or mix two flows based on the ball's position.

The valve’s design allows for precise control over the flow rate and direction. By adjusting the ball’s position, operators can manage the amount of fluid flowing through each port, ensuring optimal process control.

High-quality seals and precision machining prevent leakage and ensure reliable performance. This design aspect is crucial for maintaining system integrity and avoiding operational issues.

Choosing the appropriate multi-port ball control valve involves careful consideration of several factors:Application Requirements: Identify the specific needs of your application, including the number of flow paths and the type of fluid being controlled. Select a valve type (3-way, 4-way, or 5-way) that aligns with your process requirements. Ensure that the valve materials are compatible with the fluids handled. Consider factors such as temperature, pressure, and corrosiveness to select the right material. Verify that the valve can handle the pressure and temperature conditions of your application. Opt for a valve with appropriate ratings to ensure reliable and safe operation. Match the valve size and connection type with your system's specifications. Proper sizing and connection ensure efficient performance and seamless integration with existing infrastructure. Evaluate the ease of maintenance and the valve’s expected lifespan. Choose a valve with durable materials and design features that minimize maintenance needs and ensure long-term reliability. Multi-port ball control valves offer significant advantages for managing complex fluid systems. By understanding the various types, materials, and operational principles, you can select the right valve to enhance efficiency and performance in your specific applications.