In industries where precision, safety, and reliability are critical, the bellows sealed control valve has emerged as a game-changing innovation. Designed to handle hazardous, toxic, or valuable substances, these valves are engineered to prevent leakage and ensure optimal performance in demanding environments. This article explores the design, applications, and advantages of bellows sealed control valves, highlighting why they are a preferred choice across various industries.

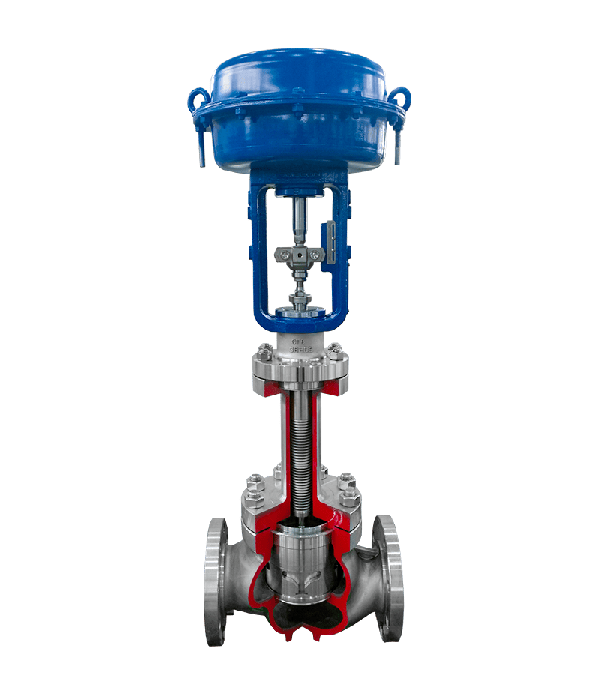

A bellows sealed control valve is a specialized valve designed to provide a hermetic seal, ensuring no process fluids escape into the environment. This is achieved through a metallic bellows that forms a robust barrier around the valve stem. Typically made from stainless steel or other corrosion-resistant alloys, the bellows is welded to both the valve bonnet and the stem, creating a leak-proof seal that is both durable and reliable.

The primary function of the bellows is to prevent fluid migration, which is especially crucial when handling hazardous or toxic substances. By ensuring zero leakage, these valves enhance operational safety and contribute to environmental protection.

The design of bellows sealed control valves reflects engineering precision and innovation. At their core is an internal metallic bellows that forms a hermetic seal around the valve stem. Constructed from materials like stainless steel or other corrosion-resistant alloys, the bellows ensures durability even in harsh operating conditions.

One of the standout features of these valves is their top-guided unbalanced structure. Known for its robustness and heavy-duty capability, this design is suitable for a wide range of industrial applications. The S-type flow channel within the valve minimizes pressure drop and maximizes flow efficiency, ensuring optimal performance.

The bellows seal single-seat control valve incorporates a double sealing mechanism, combining the bellows and packing at the bonnet. This dual-seal design ensures complete prevention of media leakage, making the valve ideal for regulating the flow and pressure of hazardous or valuable substances.

Another innovative feature is the press-in type seat design of the cage. Unlike traditional thread screw-in seat designs, this approach eliminates issues such as difficult disassembly and high leakage rates. The result is a valve with enhanced longevity and reliability, capable of consistent performance over time.

The flow-to-open configuration is another key aspect of the valve’s design. In this setup, the medium flow aligns with the valve’s opening direction, allowing for precise control over small openings and minimal distortion in flow characteristics. This feature is particularly beneficial in applications requiring precise flow control.

To further enhance versatility, bellows sealed control valves can be equipped with customized cages featuring noise reduction and anti-cavitation capabilities. These tailored solutions ensure the valves meet diverse operational requirements, making them suitable for a wide range of applications.

Bellows control valves are indispensable in industries where precision, safety, and reliability are non-negotiable. Their unique design ensures zero leakage and exceptional performance, even in harsh conditions. Key industries that rely on these valves include:

Chemical plants often handle corrosive and toxic substances. Bellows sealed control valves are ideal for these environments, as they prevent leakage and ensure safe, efficient fluid regulation.

The oil and gas industry demands robust equipment capable of withstanding extreme conditions. Bellows control valves are widely used in this sector for their ability to handle high-pressure and high-temperature applications without compromising safety.

In the pharmaceutical industry, product purity is paramount. Bellows sealed control valves prevent contamination and leakage during production, ensuring the integrity of the final product.

Power plants, whether nuclear, thermal, or renewable, require precise fluid control for efficient and safe operations. Bellows control valves are used to regulate the flow of steam, water, and other fluids.

Hygiene and safety are critical in the food and beverage industry. Bellows sealed control valves prevent contamination and ensure the safe handling of consumable products.

The semiconductor industry requires ultra-clean environments to produce high-quality components. Bellows control valves maintain the purity of process fluids, ensuring no contamination during production.

The design and construction of bellows sealed control valves offer numerous advantages, making them a preferred choice for industrial applications. Key benefits include:

The hermetic seal ensures zero leakage, making these valves ideal for handling toxic, corrosive, or hazardous fluids. This enhances operational safety and environmental protection.

The durable construction of the bellows, often made from stainless steel or corrosion-resistant alloys, extends the valve’s operational lifespan. This reduces maintenance frequency and lowers long-term costs.

By preventing external leakage, bellows sealed control valves protect personnel and the environment. This is especially important in industries dealing with hazardous substances.

The top-guided unbalanced structure and flow-to-open configuration allow for precise fluid control. This is critical in applications where even minor deviations can have significant consequences.

Customizable cages with noise reduction and anti-cavitation features ensure these valves can meet diverse operational requirements, making them suitable for a wide range of applications.

The robust design and durable materials minimize the need for frequent maintenance. This reduces operational costs and downtime, ensuring continuous efficiency.

Bellows sealed control valves are designed to meet stringent industry standards, ensuring their suitability for critical applications where compliance is essential.

Bellows sealed control valves represent a significant advancement in fluid control technology. Their unique design, featuring a sealed bellows assembly, ensures zero leakage and exceptional performance in even the most demanding environments. With applications spanning chemical processing, oil and gas, pharmaceuticals, power generation, food and beverage, and semiconductor manufacturing, these valves have become indispensable in industries where precision, safety, and reliability are paramount.

The advantages of bellows sealed control valves—zero emissions, extended service life, enhanced safety, precision control, versatility, and reduced maintenance—make them the preferred choice for a wide range of applications. As industries continue to evolve and demand higher standards of performance, bellows sealed control valves will play a crucial role in shaping the future of fluid control.

In summary, the bellows sealed control valve is more than just a component; it is a testament to engineering excellence and a commitment to safety, reliability, and environmental protection. Whether handling hazardous substances or regulating critical processes, these valves are setting new benchmarks in industrial fluid control.