How to Choose a Globe Control Valve?

On this page

Selecting the right globe control valve is crucial for ensuring efficient and reliable operation in various industrial processes. The correct choice of valve can significantly impact the performance, safety, and longevity of your system. With the myriad of options available on the market, it can be challenging to determine which valve best suits your needs. This article aims to guide you through the essential factors to consider when choosing a globe control valve, helping you make an informed decision that meets your specific requirements.

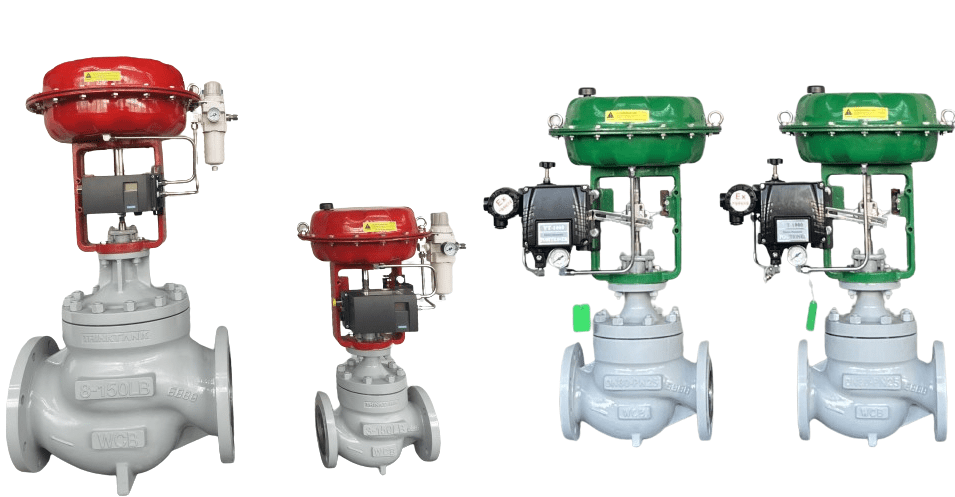

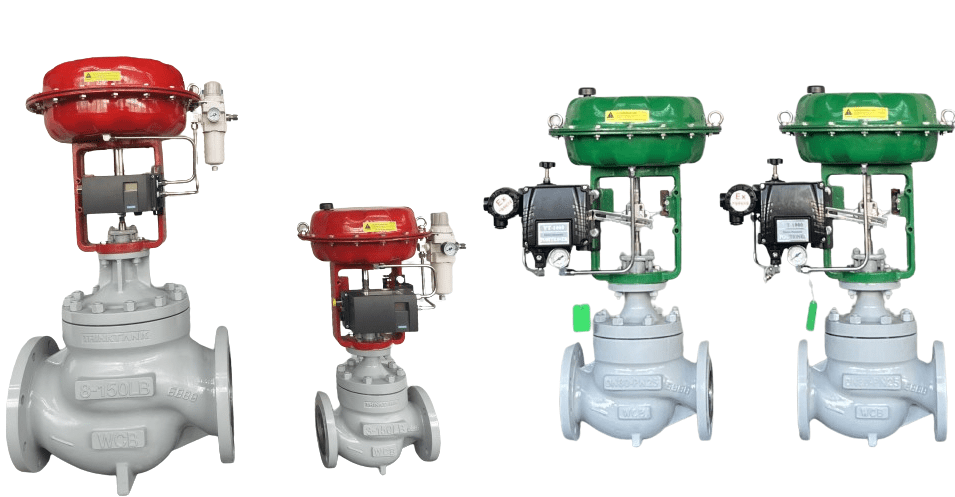

A globe control valve is a type of valve used to regulate the flow of fluids in a pipeline. It derives its name from its spherical body shape, which houses a movable disk and a stationary ring seat. The valve's design enables precise throttling capabilities, making it ideal for applications where accurate flow regulation is necessary. Globe control valves are versatile and can handle a wide range of flow rates, pressures, and temperatures, which is why they are widely used in various industries. The primary function of a globe control valve is to modulate fluid flow within a pipeline. This modulation is achieved by altering the position of the disk within the valve, which in turn adjusts the flow rate of the fluid passing through it. Globe control valves are known for their ability to provide precise control over fluid flow, making them suitable for applications requiring accurate regulation. They are commonly used in industries such as oil and gas, chemical processing, water treatment, and power generation. The valves are particularly effective in scenarios where tight shutoff and precise flow control are critical. When selecting a globe control valve, several factors must be considered to ensure optimal performance and compatibility with your system. Here are the key considerations: Choosing the correct size and type of globe control valve is fundamental to its performance. The valve size must match the pipeline size to prevent issues such as flow restrictions or excessive pressure drops. A mismatch in size can lead to inefficiencies, increased wear and tear, and potential system failures. Additionally, the type of globe valve—whether it is a straight, angle, or three-way valve—should be chosen based on the specific application and flow requirements. Each type has unique characteristics and advantages. For example, a straight globe valve is commonly used for on-off applications, while an angle globe valve is suitable for applications where the flow direction needs to change. The material of the valve is crucial to its durability and performance, particularly in demanding environments. Common materials for globe control valves include stainless steel, carbon steel, and various alloys. The choice of material should be based on the type of fluid being controlled, as well as the operating temperature and pressure conditions. For instance, stainless steel valves are ideal for corrosive environments due to their resistance to rust and chemical damage. On the other hand, carbon steel valves are preferred for high-temperature applications because of their ability to withstand thermal stress. Understanding the flow control characteristics of the valve is essential for achieving the desired performance. Globe control valves offer different flow characteristics, such as linear, equal percentage, and quick opening. The appropriate flow characteristic depends on the specific application and the level of control precision required. Linear flow characteristics provide a direct relationship between valve opening and flow rate, making them suitable for applications where steady, proportional control is needed. Equal percentage flow characteristics offer a more gradual change in flow rate, which is advantageous for applications requiring precise control over a wide range of flow rates. Quick opening characteristics allow for rapid changes in flow rate, making them suitable for applications where fast response times are necessary. In modern industrial settings, automation and remote control are increasingly important for enhancing efficiency and reducing manual intervention. Ensure that the globe control valve you choose is compatible with your existing control systems. This includes checking for compatibility with actuators, positioners, and other control devices. Integration with remote systems allows for real-time monitoring and adjustments, which can significantly improve overall system performance and reliability. Automated control systems can also provide valuable data for predictive maintenance, helping to prevent unexpected failures and extend the life of the valve. Evaluate the performance requirements of your application to select the appropriate valve. Consider factors such as pressure drop, flow capacity, and shutoff capabilities. The valve should meet or exceed these requirements to ensure reliable operation. Additionally, consider the maintenance and serviceability of the valve. Easy access to internal components can reduce downtime and maintenance costs, as routine inspections and repairs can be carried out more efficiently. Look for valves that offer modular designs or quick-change features, which can simplify maintenance procedures and reduce the time needed for repairs. The actuation method of the globe control valve is another critical consideration. Valves can be manually operated or automated using electric, pneumatic, or hydraulic actuators. The choice of actuator depends on the specific application and control requirements. Automated actuators provide precise control and can be integrated with advanced control systems, offering benefits such as remote operation and real-time feedback. Manual actuators, on the other hand, are suitable for applications where automation is not necessary or where manual intervention is preferred. When selecting an actuator, consider factors such as the power source, response time, and compatibility with the valve and control system. Choosing the right globe control valve involves a thorough understanding of your specific application requirements and the various factors that influence valve performance. By considering valve size and type, materials, flow control characteristics, compatibility with remote systems, performance requirements, and actuation methods, you can make an informed decision that ensures efficient and reliable operation. Proper selection and maintenance of globe control valves can lead to improved process control, reduced downtime, and enhanced overall system performance. Investing the time and effort to choose the right valve will pay off in terms of operational efficiency, cost savings, and long-term reliability.

A globe control valve is a type of valve used to regulate the flow of fluids in a pipeline. It derives its name from its spherical body shape, which houses a movable disk and a stationary ring seat. The valve's design enables precise throttling capabilities, making it ideal for applications where accurate flow regulation is necessary. Globe control valves are versatile and can handle a wide range of flow rates, pressures, and temperatures, which is why they are widely used in various industries. The primary function of a globe control valve is to modulate fluid flow within a pipeline. This modulation is achieved by altering the position of the disk within the valve, which in turn adjusts the flow rate of the fluid passing through it. Globe control valves are known for their ability to provide precise control over fluid flow, making them suitable for applications requiring accurate regulation. They are commonly used in industries such as oil and gas, chemical processing, water treatment, and power generation. The valves are particularly effective in scenarios where tight shutoff and precise flow control are critical. When selecting a globe control valve, several factors must be considered to ensure optimal performance and compatibility with your system. Here are the key considerations: Choosing the correct size and type of globe control valve is fundamental to its performance. The valve size must match the pipeline size to prevent issues such as flow restrictions or excessive pressure drops. A mismatch in size can lead to inefficiencies, increased wear and tear, and potential system failures. Additionally, the type of globe valve—whether it is a straight, angle, or three-way valve—should be chosen based on the specific application and flow requirements. Each type has unique characteristics and advantages. For example, a straight globe valve is commonly used for on-off applications, while an angle globe valve is suitable for applications where the flow direction needs to change. The material of the valve is crucial to its durability and performance, particularly in demanding environments. Common materials for globe control valves include stainless steel, carbon steel, and various alloys. The choice of material should be based on the type of fluid being controlled, as well as the operating temperature and pressure conditions. For instance, stainless steel valves are ideal for corrosive environments due to their resistance to rust and chemical damage. On the other hand, carbon steel valves are preferred for high-temperature applications because of their ability to withstand thermal stress. Understanding the flow control characteristics of the valve is essential for achieving the desired performance. Globe control valves offer different flow characteristics, such as linear, equal percentage, and quick opening. The appropriate flow characteristic depends on the specific application and the level of control precision required. Linear flow characteristics provide a direct relationship between valve opening and flow rate, making them suitable for applications where steady, proportional control is needed. Equal percentage flow characteristics offer a more gradual change in flow rate, which is advantageous for applications requiring precise control over a wide range of flow rates. Quick opening characteristics allow for rapid changes in flow rate, making them suitable for applications where fast response times are necessary. In modern industrial settings, automation and remote control are increasingly important for enhancing efficiency and reducing manual intervention. Ensure that the globe control valve you choose is compatible with your existing control systems. This includes checking for compatibility with actuators, positioners, and other control devices. Integration with remote systems allows for real-time monitoring and adjustments, which can significantly improve overall system performance and reliability. Automated control systems can also provide valuable data for predictive maintenance, helping to prevent unexpected failures and extend the life of the valve. Evaluate the performance requirements of your application to select the appropriate valve. Consider factors such as pressure drop, flow capacity, and shutoff capabilities. The valve should meet or exceed these requirements to ensure reliable operation. Additionally, consider the maintenance and serviceability of the valve. Easy access to internal components can reduce downtime and maintenance costs, as routine inspections and repairs can be carried out more efficiently. Look for valves that offer modular designs or quick-change features, which can simplify maintenance procedures and reduce the time needed for repairs. The actuation method of the globe control valve is another critical consideration. Valves can be manually operated or automated using electric, pneumatic, or hydraulic actuators. The choice of actuator depends on the specific application and control requirements. Automated actuators provide precise control and can be integrated with advanced control systems, offering benefits such as remote operation and real-time feedback. Manual actuators, on the other hand, are suitable for applications where automation is not necessary or where manual intervention is preferred. When selecting an actuator, consider factors such as the power source, response time, and compatibility with the valve and control system. Choosing the right globe control valve involves a thorough understanding of your specific application requirements and the various factors that influence valve performance. By considering valve size and type, materials, flow control characteristics, compatibility with remote systems, performance requirements, and actuation methods, you can make an informed decision that ensures efficient and reliable operation. Proper selection and maintenance of globe control valves can lead to improved process control, reduced downtime, and enhanced overall system performance. Investing the time and effort to choose the right valve will pay off in terms of operational efficiency, cost savings, and long-term reliability.