Steam jacketed control valves are engineered to meet the stringent demands of temperature-sensitive industrial processes. These valves are indispensable in applications where maintaining precise temperature control is essential for operational efficiency, safety, and product quality. Whether dealing with crystallization, viscosity changes, or fluid solidification, steam jacketed control valves provide a solution for industries needing reliable and consistent temperature management.

Temperature-sensitive processes are integral to industries such as food processing, petrochemicals, and chemical manufacturing. In such applications, the temperature of the medium often needs to be carefully controlled to ensure smooth processing. Steam jacketed control valves are designed to address this need by maintaining a consistent temperature, especially when the crystallization temperature of the medium is lower than the ambient temperature or when a drop in fluid temperature results in an increase in viscosity or solidification.

When fluids like oils, waxes, chemicals, or food-based ingredients cool down too quickly, they can undergo significant changes in their physical properties. These changes—such as thickening or solidification—can lead to equipment blockages, reduced flow rates, and processing inefficiencies. Steam jacketed control valves prevent these issues by ensuring the fluid remains at an optimal temperature for smooth flow and processing.

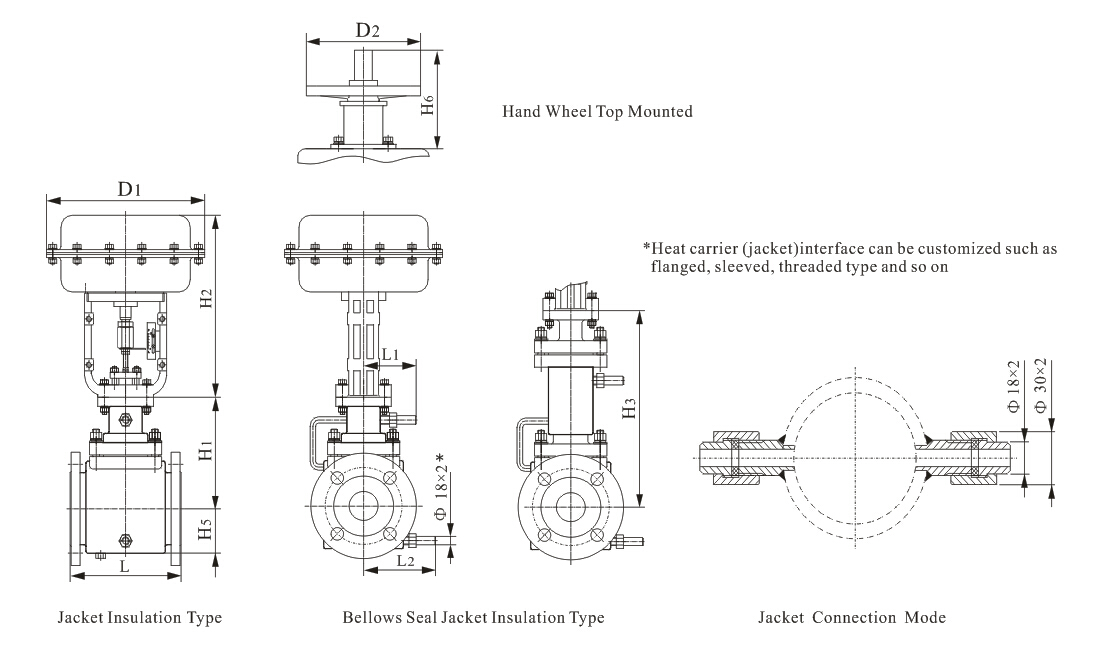

A key feature of steam jacketed control valves is their use of insulated valve jackets, which are specifically designed to maintain the desired temperature range for a variety of valves. This insulation is critical in a wide range of applications and can be applied to different valve types, including jacket ball valves, jacket plug valves, and jacketed butterfly valves.

Each type of valve is equipped with an advanced steam insulation jacket device that wraps around the valve body and upper valve cover. This innovative design ensures that the temperature of the process medium is kept in a stable condition, which is vital for the continuity and efficiency of the production process. The insulated jacket works by circulating steam around the valve to maintain a constant temperature, preventing the medium from cooling too quickly and thereby avoiding the risks associated with temperature fluctuations.

This adaptability makes steam jacketed control valves particularly beneficial in industries where precise temperature control is critical. The ability to choose between different valve types based on process requirements further enhances the versatility of these valves.

Steam jacketed control valves are built to operate efficiently under challenging conditions, with an emphasis on both temperature regulation and performance consistency. The design of these valves meets the stringent ANSI B16.104 leakage standards, ensuring minimal fluid leakage. This high level of performance is critical in applications that deal with hazardous or sensitive fluids where even the smallest leak can lead to serious operational disruptions or safety hazards.

To further enhance performance, these valves often include a multi-spring diaphragm actuator. This actuator is designed to generate large output forces in a compact, space-efficient structure. The multi-spring diaphragm actuator offers improved responsiveness, which is especially important for precise control of flow rates in applications where the process medium’s properties can change rapidly due to temperature shifts.

Whether dealing with volatile chemicals or temperature-sensitive fluids, the combination of minimal leakage and a powerful actuator ensures these valves deliver precise control. This makes them particularly well-suited for industries like petrochemical manufacturing, pharmaceuticals, and food processing, where even slight variations in temperature can compromise product quality or cause production delays.

The most notable feature of steam jacketed control valves is the use of steam insulation jackets, which maintain the stability of the valve temperature. This thermal insulation ensures that the process medium stays within the desired temperature range, preventing issues like crystallization or thickening. The use of insulation jackets allows for flexible application across various valve types, including jacket ball valves, jacket plug valves, and jacketed butterfly valves.

Steam jacketed control valves are designed with compliance to ANSI B16.104 leakage standards, ensuring minimal leakage during operation. This is vital for maintaining system integrity and preventing costly fluid loss, especially in systems where the process medium is valuable, hazardous, or sensitive. The high level of leak-tightness provided by these valves guarantees safe and efficient operation in critical processes.

These valves are equipped with multi-spring diaphragm actuators, offering high output forces while maintaining a compact and efficient design. The actuator is capable of responding to temperature-induced variations in fluid viscosity, providing real-time adjustments to maintain the desired flow rate and process conditions. This feature enables precise and effective flow control, even in applications with varying fluid properties.

Steam jacketed control valves excel at controlling fluids that are prone to solidifying, crystallizing, or thickening due to temperature fluctuations. Their ability to keep the process medium at a stable temperature ensures that these fluids remain in a suitable condition for optimal flow and processing, thereby improving operational efficiency and reducing the risk of costly production downtime.

Steam jacketed control valves find application in several industries, particularly those where maintaining the temperature of process media is crucial to achieving optimal results. Some key sectors that benefit from these valves include:

In food manufacturing, certain ingredients, such as oils, syrups, and fats, are sensitive to temperature changes. Steam jacketed control valves ensure that these ingredients stay at the correct temperature, preventing crystallization or thickening that could negatively impact product quality. These valves are essential in maintaining product consistency and meeting regulatory standards in the food processing industry.

In petrochemical processing, many fluids, such as oils and liquid gases, must be kept at precise temperatures to maintain their flow characteristics. Steam jacketed control valves are often used to prevent these fluids from solidifying or becoming too viscous, ensuring continuous and efficient flow through pipelines and reactors. The reliability and leak-tight nature of these valves are crucial in preventing accidents and maintaining system stability in petrochemical plants.

Chemical manufacturing processes frequently involve the use of highly sensitive chemicals that react differently at various temperatures. Steam jacketed control valves help maintain the required temperature levels for these chemicals, ensuring that they stay in a liquid or flowable state and do not crystallize or thicken. By maintaining consistent temperatures, these valves enable more controlled and efficient reactions in chemical reactors, leading to higher yields and improved process stability.

In the pharmaceutical industry, temperature control is vital for ensuring the integrity of raw materials and finished products. Steam jacketed control valves are used in processes involving sensitive pharmaceutical ingredients that could degrade or lose potency if exposed to temperature variations. These valves are designed to provide precise control of temperature during manufacturing, which is essential for maintaining the high quality and safety standards required in the production of pharmaceutical products.

Like pharmaceuticals, the cosmetics industry relies on precise temperature control to ensure the consistency and quality of creams, lotions, and other products. Steam jacketed control valves help maintain stable temperatures during production, preventing ingredients from solidifying or degrading. This helps manufacturers produce high-quality, consistent products that meet consumer expectations.

The oil and gas industry uses steam jacketed control valves to regulate temperatures in various processes, including refining and transport. These valves ensure that crude oil and other hydrocarbons maintain their desired flow properties, even in cold environments or during transport through pipelines that may experience significant temperature fluctuations.

Steam jacketed control valves are a critical component in industries where maintaining the temperature of fluids is essential to efficient and safe operation. From food processing to petrochemicals, these valves provide the precision and reliability needed to manage temperature-sensitive media. By offering a range of valve types, compliance with rigorous leakage standards, and advanced actuator designs, steam jacketed control valves help industries prevent issues such as crystallization, viscosity increases, and solidification. Their versatility and efficiency ensure they continue to be indispensable in temperature-controlled applications across various industrial sectors.